The WWT Non-Rotating Silencer assembly is placed in or near the BHA to dampen downhole vibrations, reduce stick-slip, lower torque, assist directional control, and provide more efficient transfer of mechanical energy from top drive to bit. The WWT Silencer provides these benefits by using a non-rotating stabilizer with a low friction fluid bearing design. The non-rotating sleeve is manufactured using a proprietary vibration absorbing polyurethane material bearing encapsulated around a steel or non-mag mandrel. The non-rotating sleeve is designed to be a sacrificial element, absorbing vibration energy from the drill string, thereby protecting critical BHA components. The WWT Silencer is designed as a fail-safe product without any fastening hardware or metallic parts within the non-rotating sleeve. The non-rotating polyurethane sleeve is fully drillable with nearly any kind of bit. If a non-rotating sleeve were to fail, the sub mandrel is essentially a short piece of HWDP, which allows operators to continue drilling ahead rather than tripping for a failed BHA component.

Benefits:

- Interior geometry provides hydraulic and elastomeric dampening of axial and lateral vibrations.

- Hydrodynamic bearing reduces torsional friction, thereby mitigating torsional oscillations.

- Combined benefits results in improved drilling efficiency with increased BHA & bit life.

Features:

- Non-rotating stabilizer sleeve, manufactured from a durable high-performance polymer.

- Mandrel is manufactured from one piece of high strength steel or non-magnetic alloy. Excellent strength and fatigue resistance.

- Replaceable, fail-safe non-rotating wear sleeve.

- Field proven materials based on 30+ years of downhole experience with WWT’s Non-Rotating Protectors product line.

- Large flow channels to allow for cuttings and fluid flow.

- Designed to work near or within the BHA to improve overall drilling performance

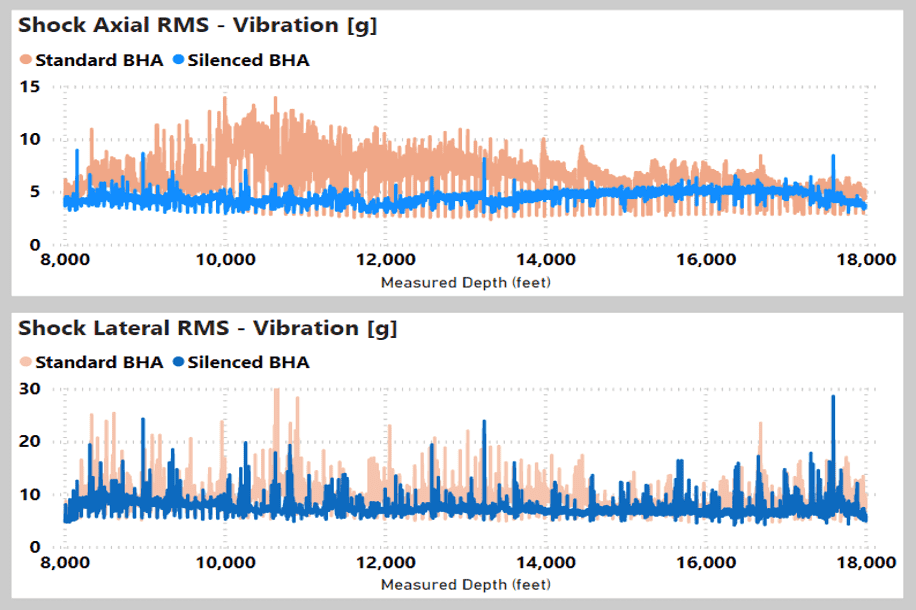

Comparing pad wells using the exact same BHA only replacing a stabilizer with the WWT Silencer.

Download and complete WWT's well data sheet, which details info required for a complimentary analysis.

Go to Case Histories and filter Product to 'Silencer' for more information: https://www.wwtco.com/solutions/case-histories/