WWT NRPs Reduce Torque, Drag, and Carbon Footprint

High torque experienced while drilling challenging offshore wells affects equipment integrity and drilling efficiency. Over-torqued drill pipe, fatigued top drive system, or even reduced drilling parameters, are some of the challenges that WWT Non-Rotating Protectors (NRPs) can help mitigate.

Client challenge

An Operator in the North Sea experienced high torque while drilling a horizontal well causing a drill pipe twist-off and loss of BHA downhole.

Our solution

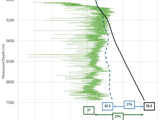

Using WWT NRPs while drilling 2 x 12-1/4” sections and 1 x 8-1/2” section provided the needed torque reduction to successfully reach TD. NRPs covered the build section inside the casing where the side forces were the highest.

Results

Backmodel shows that at TD, torque was reduced by up to 27% and drag by up to 50 tons in pick-up weight. This equates to savings in diesel consumption of around € 3,500 per day, and over 6 tons daily reduction in CO2 emissions.